Printed film and pouch packaging mockups for food and products – which materials are used?

Gaining real life insights into how a product looks when printed and how it appears on shelf amongst competitors enables you to deliver killer pitches to buyers! So the materials used and the print process will show you how it should be on the retail shelf!

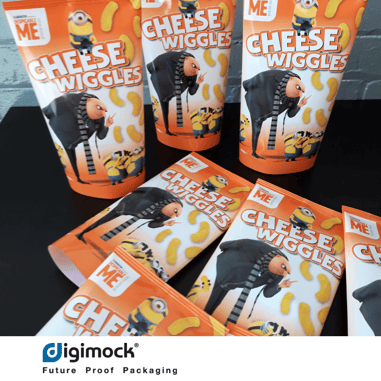

Our mockups or Digimocks are unique – they are constructed with materials used on full production lines, ensuring the finished mockup packs are an accurate representation of the final product. By using the widest range of flexible packaging material options available and using the latest Digital printing presses, every mockup is matched to pantone and constructed with accuracy.

Why does this matter?

There’s a vast range of materials used for food, beverage and product packing for retail and we advise on the correct materials based on what clients would need to use for a full production. Then it’s about working back from the ideal solution to ensure the mockups match as closely as possible.

This is important, as different materials have different properties – for a printed stand up pouch PET/PE structures are more tensile than OPP/OPP structures, and more heat resistant, and so has less chance of ‘drooping’ when standing up. For a printed flow wrap or pillow pack, OPP structures are more widely used as, amongst other reasons, they don’t need to stand up on shelf.

From a more practical point of view, using the same materials for mockups and full production enables you to truly understand the nuances of your printed pouch or printed film, and reduces the risk of any surprises. Of course, material structure selection can be complex and Digimock is perfectly positioned to advise and help clients navigate through this technical process.

Why do clients use Digimocks?

With the mainstream print technologies of Digital, Flexographic and Gravure printing, clients want to establish high standards before full production and Mockups create a benchmark for proofing and final pack format approval.

When taking a new concept or a brand from the design stage to finished product, it’s important to understand every client’s needs - from commercial, technical, design to marketing and sales functions. And a mockup captures the input of every part of product development team as a product begins the journey to market, maximising the opportunity to ensure successful sales. Being able to visualise your brand’s future early on is important as it enables you to proceed through your pack’s life with the comfort of knowing from the beginning of its life - you’ll know what you receive at the end!

Future proofing your packaging today - a proven way to ensure product success!

Please subscribe and be amongst the first to receive informative news, views and updates from Digimock about flexible packaging.